TechnoConfluence

Intelligent Engineering solutions pvt. ltd.

Unifying Knowledge

40+ years of Leadership experience in Technical Marketing and Global Business Development with one of the most prestigious Indian Public Sector undertakings, BEML. Prior to undertaking the reigns of TechnoConfluence, he held several important positions and in the last lap of his career, headed Brazil operations for BEML.

35+ Years of Experience in the Development and Manufacturing of more than 50 Power Electronics products and derivatives in R & D Laboratories and Technology driven Industries using New product development processes leading to more than USD100 M of Manufacturing Revenue per annum in Premium industries like GE, APC, Schneider, Bloom Energy, SunEdison, Infineon etc. Experience in Design for 6-Sigma using various tools like QFD, FMEA, Root cause Analysis, Minitab etc. Management and leadership experience of setting up laboratories, Design Centers and Indian subsidiary companies for MNCs and led positions at India, APAC and Global levels for Design, Manufacturing and Application Engineering.

35+ Years of Experience in R & D Laboratories, Advanced Technological Institute and Technology driven Industries, specifically in the areas of Structural Design and computational Mechanics (Finite Element Analysis, Classical Methods, Statics, Dynamics and Structural Instabilities, Vibration & Aero-elasticity, etc.). Proven Expertise in Advanced Composite Structures, Smart Structures, Functionally Graded Material Mechanics and Nano-Mechanics. Prior to being part of TechnoConfluence, he held several Leadership positions in defense and aerospace companies.

20+ years of experience in R & D Labs. Organizations, Institutes and Technology driven Industries, specifically in multidisciplinary and trans-disciplinary areas encompassing Structures, Remote Sensing, Electronics, Aerospace, Parallel Computing, Instrumentation and Control System Engineering.

19+ years of experience in R&D, Modeling, Product Design, Project Management, Product Testing & Reliability, New Product Development & Product Validation in diverse areas of Power Generation, Healthcare and Transportation. His previous work experience includes stints at GE’s Global Research and Bloom Energy where he worked on development of several innovative technologies in the domains of Transportation, Healthcare, Aviation and Energy.

16+ years of experience in R&D organizations and Technology driven Industries specifically in the areas of micro/nano Devices and systems Design, Semiconductor Technology, building state of the art sensors and sensor networks, development and operation of state-of-the-art electronics fabrication and characterization facilities.

In addition to the core team, we have 150+ Subject Matter Experts from diverse disciplines of Science and Engineering, capable of transforming Technologically Challenging Problems into Innovative Solutions.

Robust and Reliable products are an outcome of extensive characterization of components, sub-systems, and systems under accelerated real-time conditions. TechnoConfluence excels in developing calibration protocols, device calibration, innovative cutting edge test and characterization facilities to address all aspects of product verification and validation, modernization of existing test facilities, all the way up to pre-qualification and pre-certification tests across disciplines.

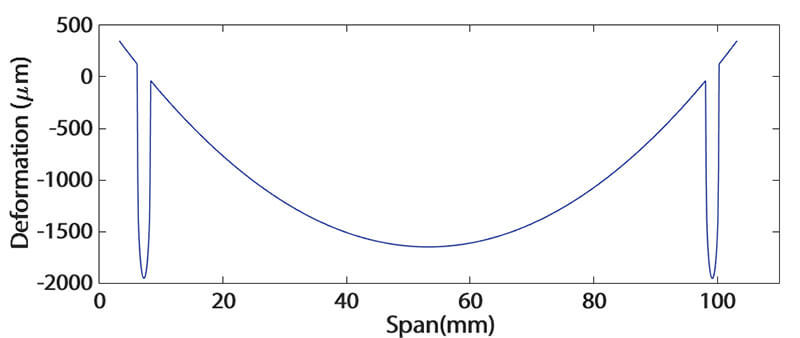

Thermo-Mechanical Characterization using Non-Contact Deformation Measurement Techniques

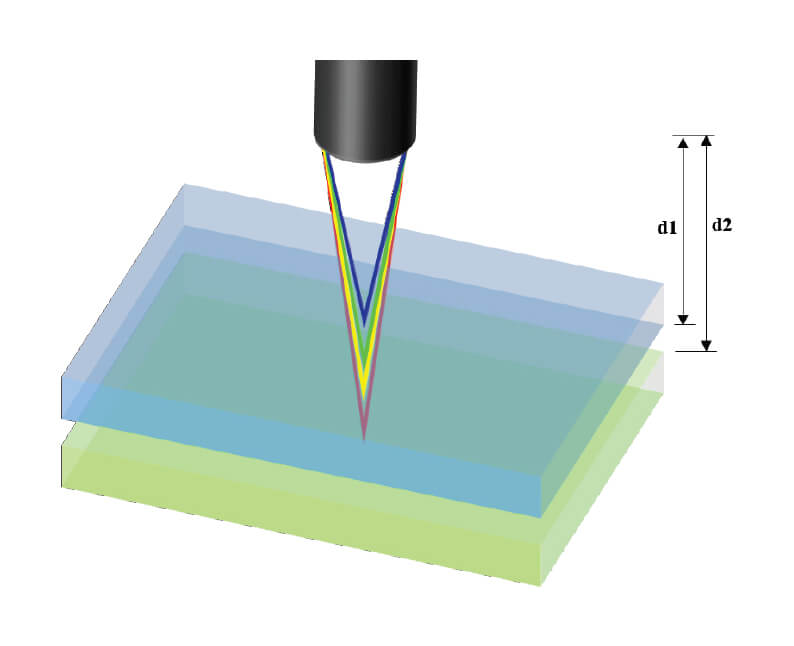

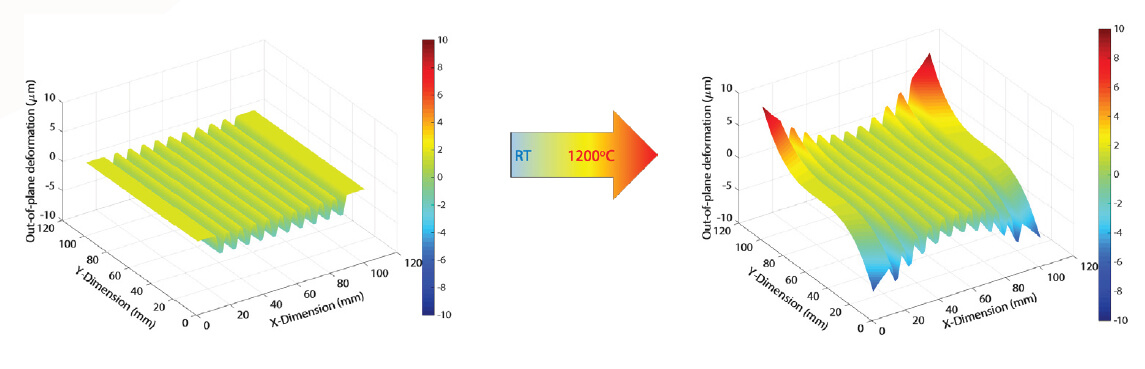

Our state-of-the-art “High Temperature Non-Contact Material Characterization” test system, initially developed to measure surface profiles of components in-situ, up to temperatures as high as 2000 ℃, has evolved into a mechanical characterization tool to handle diverse materials like ceramics, metals, glasses, polymers, composites etc., under diverse environmental conditions like oxidizing, reducing, inert, vacuum, humid and ambient conditions. Choice of 9 different sensors to suit specific customer requirements makes this test set-up highly customizable.

Enhancements to this non-contact test system include handling higher temperatures up to 2000oC to measure deformation profiles, yielding accuracies close to few tens of a nanometer in out-of-plane deformation measurements.

Industries having high degree of interest in thermo-mechanical tests at elevated temperatures including Energy, Aerospace, Defense, and Automobile in addition to R&D institutions and academics involved in high temperature material development and characterization will find this test system indispensable.

Key Features:

- In-situ Material/Mechanical Characterization at High temperature up to 2000 ℃

- Non-contact Differential measurement

- Accurate measurement of complex profiles of components, subsystems, etc.

- Different levels of resolution (10nm to 10um) and sampling rates (few Hz to 70 kHz)

- Flexibility in material type (metals, glasses and ceramics)

- Open architecture to accommodate novel test and characterization requirements

- Access to raw data in addition to test specific post-processing as per ASTM standards

- Controlled test environment (Oxidizing, Reducing, Inert, controlled humidity, etc.)

- User defined temperature protocols

- Option for visualization of specimen during test

- Option for implementation of automated test procedures

- Option for configuration as an online quality control (QC) tool

- Customization and Adaptation available for novel test procedures

- Tensile and Compression Test (Including Creep Test)

- Three and Four Point Bend Test (Including Creep Test)

- Fracture Toughness Measurement

Our Solution: A novel “non-contact” 2-D/3-D differential profile measurement technique overcomes limitations of point based techniques (strain gauges, LVDTs etc.) by capturing entire deformed profile in-situ. This proprietary technique enables measurement of entire sample profile (deformation) including support displacements at any given instant in time, up to testing temperatures of 2000 ℃ in-situ, thereby eliminating errors related to boundary conditions.

Challenges: Characterization of glasses near their glass transition (Tg) and metals near their melting point require accurate measurements of deformed sample shapes and time lag with respect to loading profile.

Challenges: Characterization of glasses near their glass transition (Tg) and metals near their melting point require accurate measurements of deformed sample shapes and time lag with respect to loading profile. Our Solution: Capability of one-sided differential thickness/gap measurements enables characterization of glasses above their glass transition (Tg) by placing samples between transparent plates. Time history of change in thickness (deformation) with respect to applied load profile is captured accurately. In addition to thickness change, lateral deformation time history provides complete information about the viscoelastic behavior of the material.

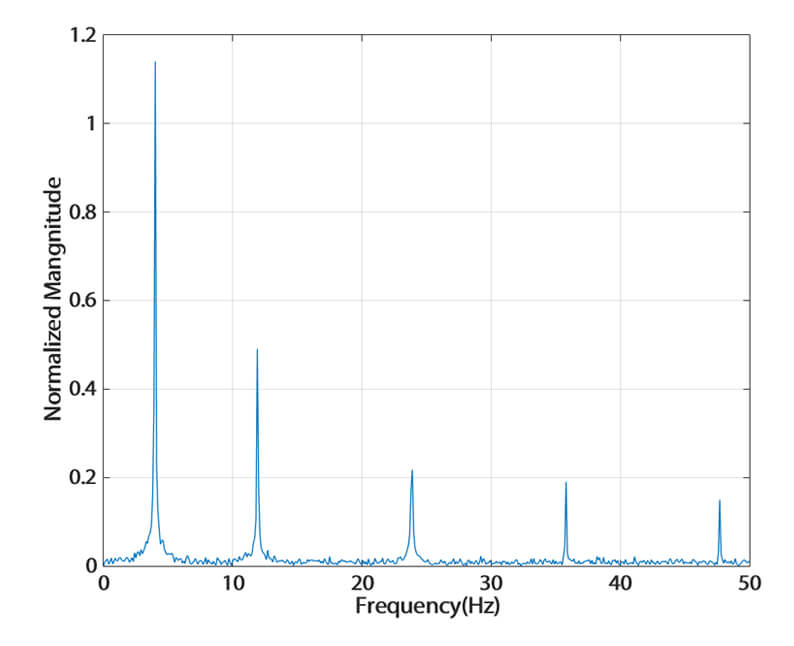

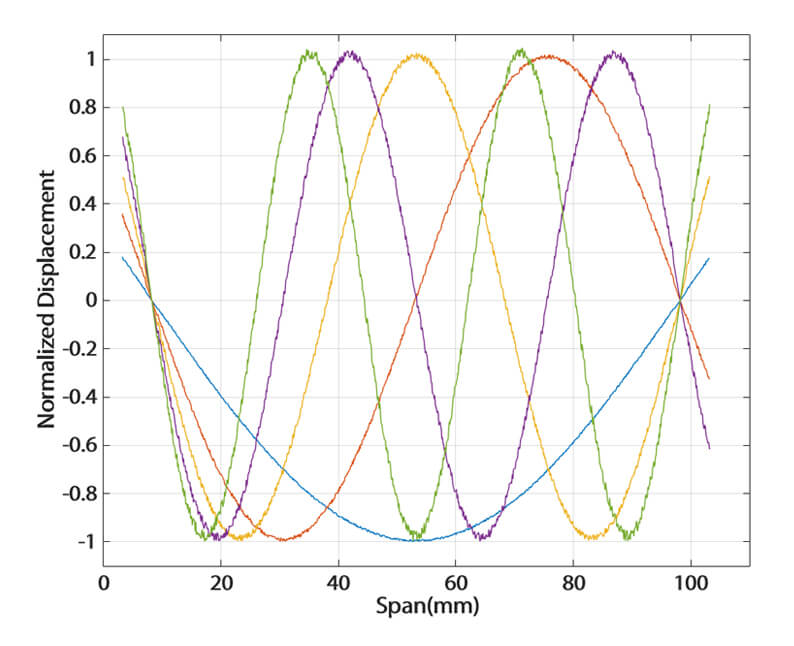

- Impulse Test (natural frequencies and mode shapes)

- Forced Excitation/vibration test

Our Solution: Our unique differential displacement measurement captures entire profile thereby providing complete information of frequencies and mode shapes. For very accurate resonant frequency measurements, a specialized forced excitation test is also available as add-on in our vibrometry test suite.

Our Solution: Our in-situ measurement technique captures specimen/part profiles at high temperatures and under varied operating conditions (like oxidizing, reducing, humid etc) to measure profile changes in real time thus enabling accurate control of process parameters. Options are available for 3-D scan/ simultaneous capture of highly featured surfaces and real-time curvature measurements up to 2000 ℃.

- Thermal/Environmental Chamber

- Temperature Range: RT-1600 ℃ (optional extended range: below RT-2000 ℃)

- Heating/Cooling rate: upto 10 ℃/min (higher rate optional)

- Uniformity of temperature over the sample under test: better than 2 ℃

- Chamber Temperature Accuracy: ±3 ℃

- Number of ramp and soak segments: 16 (Higher numbers are available as option)

- Load Controlled Test

- Maximum load : 200N*

- Load resolution: 0.1N*

- Frequency Range: Static to 10kHz

- Displacement Controlled Test

- Maximum displacement: 28mm**

- Displacement Resolution: 10nm**

- Frequency Range: Static to 10kHz

- Profile Measurement Sensor

- Max Measurement range: 28mm

- Best Resolution: 30nm

- Sampling rate: upto 70kHz

- Scanning resolution: 100nm***

- Simultaneous Profile capture: Yes (Optional)

- Control Computer with extended display and Software available as standard feature

- * better load resolution is available for smaller load range

- ** depends on the profile measurement sensor range

- *** better scanning resolution is available for shorter scanning range.

- Intelligent Engineering Solutions Pvt. Ltd.

- World Trade Center, 22nd floor,

- Unit No. N 2201A, Brigade Gateway Campus,

- Malleswaram West, Bangalore-560 055, INDIA.

- Phone : +91 80 6793 5687

- Fax : +91 80 6793 5301

- Cell : +91-789 972 9061

- E-mail : ceo@technoconfluence.com

- Web : www.technoconfluence.com

Home

Home